Mac Hodell, global director of management consulting – strategic planning services

As management consultants, we have special opportunities to partner with our clients to improve decision-making and strategic planning activities to drive success. What is even more rewarding and interesting, however, is when we have the opportunity to learn from our clients and understand how they address challenges. This post describes one recent example.

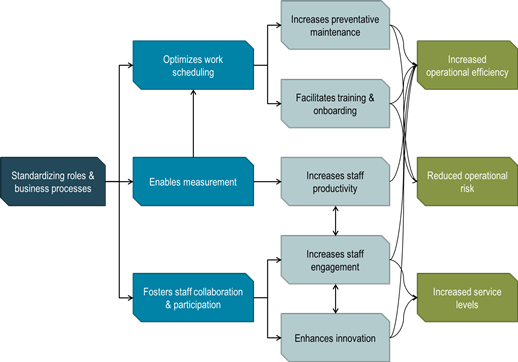

During some recent benchmarking work, I had the opportunity to talk with leadership teams from several top utilities about what tactics and techniques they attributed to their success. One might have expected to hear things like, “a strong asset management program,” or “cutting-edge IT solutions.” Instead, each leadership team cited something far more basic: standardization of roles and operational processes. Going even further, each described the effectiveness and efficiency benefits they gained from multi-year efforts.

Interestingly, standardization yielded benefits in two ways. Initially, the process of standardization can improve both engagement and efficiency. Then, with those standards in place, the organizations saw increases in efficiency and service levels, and reductions in operational risks.

Benefits from the process of standardization

Organizational Engagement: By encouraging skilled staff to provide input regarding standards for roles and processes, utility leaders improved the quality of the standards by tailoring to the reality of each particular utility. In addition, staff in those utilities demonstrated greater acceptance of the changes, which enhanced employee engagement.

Process improvement via cross-functional collaboration: By bringing together staff from various business functions, utility leaders identified process improvements. Simply assembling the different parties involved in a given process and asking how to standardize it revealed opportunities for redesign, centralization and simplification.

Benefits of employing standardized roles and business processes

Optimizing work scheduling: Open discussions allow team supervisors and planners to understand how long different tasks truly take leading to a decrease in task duration variability. This predictability enables more preventative – or scheduled – maintenance to occur, yielding compelling cost advantages.

Managing based on data: The implementation of performance standards allows process times, productivity and quality metrics to become comparable across teams. With comparable measurement comes incremental improvement as crews compete to beat the standard.

Onboarding new staff: Standardization shortens the time needed for onboarding new staff, which reduces the risk from aging workforce retirement. This also enables utilities to recruit slightly underdeveloped staff and build them up internally, which increases morale and loyalty while lowering staff costs.

Encouraging innovation: Perhaps surprisingly, implementing standard operating procedures frees employees’ minds to innovate in other areas and share internal best practices, especially when a culture embraces decentralized continuous improvement and standardizes development of this intellectual property. Data-based measurement and reporting stimulates internal best-practice sharing.

In a field often caught up in the “new thing,” it is refreshing to hear utility leaders describe the incredible impact of old-fashioned process discipline.

Do you have these basic principles in place at your organization?

How do you feel about the degree of standardization of your operational roles and processes?